Sewage Collection System - The Vacuum Way

Introduction

- Iseki-Redivac are market leaders in Vacuum Sewerage Collection Systems and have more than 25 years experience Worldwide. Where difficult ground conditions make conventional gravity collection uneconomical, Redivac's high performance vacuum systems can offer a significant reduction in the overall cost of a project.

- Vacuum sewerage technology is ideal in areas which are flat with a high water table, rocky terrain, and sandy landscapes or for special applications such as villages built on piles.

- Iseki-Redivac small bore pipework is laid approximately one meter below ground level reducing digging costs by up to 40%.

- Iseki Vacuum Systems currently have a total of 11 vacuum systems installed to the United Arab Emirates and Oman with over 3,700 number 90mm Interface Valves in operation.

- All our Middle East systems include the use of our advanced PLC based Individual Interface Valve Monitoring and Control System and our very robust Iseki Middle East Specification which has been developed during the past 23 years.

How it Works?

Redivac's vacuum system can be used to collect a variety of fluids, the most common of which is the collection of sewage from within domestic housing developments.

The three main components of a vacuum sewerage system are:

-

Valve Chambers

These collect effluent discharged from the connected properties and allow the collected sewage to enter the vacuum sewer network via the Redivac interface valve.

-

Vacuum Sewers

These form the pipe network which is under vacuum and allows the sewage to be transported to the vacuum station.

-

Vacuum Station

This is the operation center from where the whole of the vacuum sewerage system is controlled and monitored. Here the vacuum pumps generate the vacuum throughout the system and it is where the sewage is held in the collection vessel. From here it is pumped to the sewage treatment plant or nearby gravity sewer.

Sample Projects

METCO/ISEKI, has for many years performed and installed Vacuum sewage systems on turnkey basis. Since the first project, Zayed Sport City Stadium in Abu Dhabi back in 1994 until the latest Al Gurm Resort project in 2011, both companies have provided a unique and reliable system operating without interruption

-

AI Gurm Resort- Residential Vacuum Sewerage System

The project comprises a vacuum collection system with the vacuum station centrally located between the land villas.

Effluent is collected by gravity from individual villas to dedicated valve chambers sited in the vicinity of the villa. The effluent enters the vacuum sewer network through a vacuum interface valve installed within each valve chamber.

The sewer network is constantly under vacuum and as the valve opens the differential pressure forces the effluent into the network and onward transport to a vacuum vessel located at the vacuum station. The vessel acts as a vacuum receiver and storage facility for the effluent prior to discharge.

The vacuum station comprises ten cubic meter vacuum vessel, three 500 m3/hr vacuum pumps and two dry well horizontal screw centrifugal discharge pumps. The effluent is pumped through a 180mm diameter rising main to a gravity sewer located approximately 950 meters to the East.

No. of Vacuum Chambers: 69 units Length of pipe work below ground: 5.20 km Piping Works

-

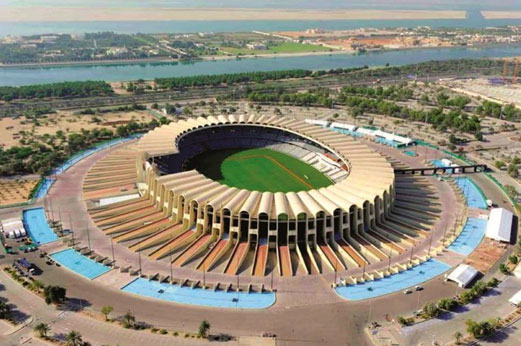

Zayed Sports City Stadium

The Stadium plumbing and waste water collection system lies deep within the structure and finds its way into a gravity collector sewer at depths exceeding 4 meters.

Located in saline water conditions with an upper surface just below the ground level, the prospects of re-laying the sewer in such ground conditions was a daunting if not impossible task. An alternative consideration to reline the damaged pipes was also very difficult primarily due to severe access problems.

Iseki offered the vacuum technology as a solution. The proposal was to intercept the incoming gravity flows above ground in collection sumps and via a vacuum interface valve and ring main collect the sewage in a steel vessel located in the vacuum station cleverly positioned beneath the seating.

Vacuum Pipework

200 mm diameter polyethylene pipework around the service gallery connecting into the vacuum station.

Length of Pipe: 300 m No. of Valves: 36 Volume of Flow: 50 liters/second Vacuum Station Equipment

- 3 No. rotary vane vacuum pumps each rated at 400m³/hr

- 2 No. dry well discharge pumps each rated at 50 l/sec

- Vacuum collection vessel volume – 16 m³ fully protected with epoxy coating and tested to Lloyds certification

- Motor control cabinet - fully automatic with switchable programmable PLC

- Bespoke valve monitoring system which monitors the open/close mode of each interface valve located around the stadium

Exhaust gases are filtered by passing them through an activated carbon filtration unit and are finally discharged via a vent stack to the rear of the stadium.

-

University City - Sharjah

Vacuum Pipework

Vacuum sewers in PN10 polyethylene sizes from 90mm-200mm with electro-fusion joints.

Length of Pipe: 44 km No. of Valves: 410 Volume of Flow: 4 stations each 50 litres/sec Vacuum Station Equipment

Four stations each operating with three rotary vane vacuum pumps each rated at 400m3/hr (Busch) together with two dry well discharge pumps each rated at 50 l/s (full duty).

Vacuum collection vessel 25m 3 fully protected for Middle East conditions and tested to Lloyds certification. Motor control cabinet fully automatic with a PLC. All pumps start in rotation and all conditions are monitored with a data logging system.

Bespoke vacuum interface valve monitoring system which monitors the open/close mode of each valve at all locations around the project.

-

ADDCAP Offshore Base – Abu Dhabi

Abu Dhabi Drilling Chemicals and Pipes are suppliers of materials to the oil and gas industry. Following the decision to move from their island base a few miles off the coast, a new site was selected on the mainland close to Abu Dhabi city. This new supply was to be located on a flat low lying area of desert sand adjacent to the Gulf. To be built on the new site was a central office block together with storage facilities, with warehousing that would develop as demand required. Provision was to be made within the vacuum sewer network design for the future addition of an accommodation block for employees on the base.

Vacuum Pipework

The polyethylene pipework around the Base ranges in size from 90mm to 160mm diameter.

Length of Pipe: 3000 m No. of Valves: 32 Volume of Flow: 10 litres/second Vacuum Station Equipment

- 2 No. liquid ring vacuum pumps each rated at 370 cubic meters/Hr (Nash) acting.

- 2 No dry well discharge pumps at 10 l/s.

- Vacuum collection vessel volume- 16 m3 fully protected with epoxy coating and tested to Lloyds certification.

- Motor control cabinet - fully automatic with programmable PLC.

-

SEEB Vacuum Sewerage System – Muscat, Oman

In May 2008 ISEKI-REDIVAC were awarded the contract to supply 7 vacuum stations and more than 2500 Iseki Vacuum Interface Valves to the Seeb Vacuum Sewerage System in Muscat, Oman. This project will be completed in August 2016.

2005 Supplied new Iseki vacuum system installed in Abu Al Shaoom Island, Abu Dhabi. This 20 l/s vacuum system was designed to serve a palace and villa complex. 2007 Supplied Iseki Vacuum Interface Valves and Vacuum Station Equipment to be installed to the Free Zone vacuum system in Ras Al Khaimah. 2008 Supplied Iseki Vacuum Interface Valves and two additional Vacuum Pumps to be installed to Phase Two of Al Hamra vacuum system in Ras Al Khaimah. 2015 We have supplied design and supply of Redivac Interface Valves to Phase 4 of the AL Hamra vacuum sewerage system in Ras Al Khaimah. 2009 to 2016 We supplied materials and equipment to the University City of Sharjah for the construction of Phase VII at the University. The system now includes 4 vacuum stations and in excess of 800 number 90mm Iseki Vacuum Systems (Redivac) interface valves.

-

Advantages of ISEKI Vacuum Systems

- Vacuum sewerage technology uses shallow, narrow trenches which can be easily excavated, helping to speed up the construction of the project.

- The adaptability of the small bore polyethylene piping allows construction of a pipe network reaching all areas of the site without the need for large and sometimes deep collector pipes. The vacuum system can be integrated with existing gravity systems and septic tanks and can be designed to accommodate future phases of expansion to the site.

- The location of the vacuum station is not critical within the site, which enables it to be positioned on an area of land which may not be suitable for domestic development. Collection chambers throughout the site do not need electrical power keeping installation and operating costs to a minimum.

- Redivac vacuum systems are sealed and self contained, thus eliminating the risk of contamination to the ground resulting in an environmentally sound solution.

-

Applications

- Rural Community Main Sewage.

- Roof Drainage.

- Camp & Caravan Sites.

- New Housing Development.

- Old Towns with Narrow Streets.

- Hospitals Effluent Collection.

- Shopping Centers with difficult or Confined Areas.

- Replacement of Conventional Gravity Systems.

- Factory Sewerage.

- River, Lake & Coastal Communities.